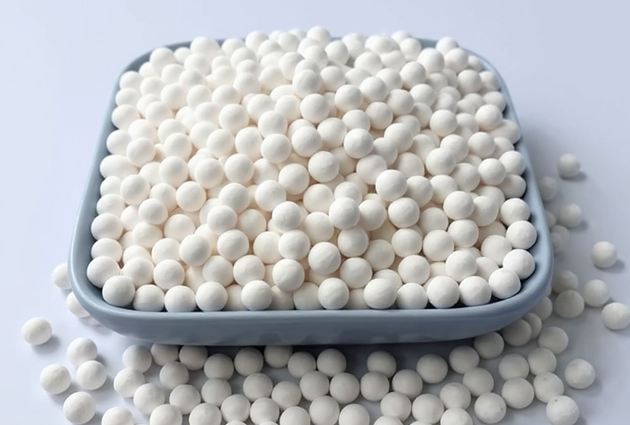

Activated Alumina

Global Adsorbents is a leading activated alumina manufacturer. We specialize in manufacturing high-quality activated alumina solutions for a diverse range of industrial applications. We supply high-quality Activated Alumina to leading companies across India and export globally to meet diverse industrial applications.

Activated Alumina for Water Treatment and Industrial Use

Super Performance Activated Alumina - Global Aluminoxite

Made by de-hydroxylating aluminum hydroxide, Global Aluminoxite is a proprietary offering in our activated alumina line, engineered for exceptional adsorption performance and a long service life. The key features include:

Generates a high-surface porous structure

Exhibits stellar adsorption characteristics to remove a variety of contaminants

Surface area up to 350 m2/g

High attrition resistance and crush strength, has larger water adsorption capacity as well

Provides a long service life with performance at or below dew point specifications

Premium Grade Activated Alumina impregnated with Potassium Permanganate ( KMnO4)

Impregnate activated alumina with Potassium Permanganate to enhance the adsorption characteristics of the particular activated alumina.

Effective Air Purification with Potassium Permanganate

Potassium permanganate’s powerful oxidizing capabilities will effectively neutralize harmful airborne molecules

It efficiently mitigates compounds like hydrogen sulfide (H2S), sulfur dioxide (SO2)chlorine (Cl2), formaldehyde (HCHO), and nitric oxide (NO), ensuring cleaner air in industrial and/or commercial settings. It is also used to remove iron and hydrogen sulfide from water sources.

Activated Alumina Applications and uses

Polyethylene Manufacturing

Used in the purification process by removing impurities that affect catalyst efficiency.

Hydrogen Peroxide Production

Acts as a selective adsorbent and stabilizing agent in the anthraquinone process.

Fluoride and Arsenic Removal

Widely used in water treatment systems to adsorb toxic elements from drinking water.

Claus Process (Sulfur Recovery)

Serves as a catalyst in converting hydrogen sulfide (H₂S) into elemental sulfur in gas processing plants.

Amines Alkylation in Refineries

Functions as a catalyst or catalyst support in the synthesis and treatment of alkylated amines.

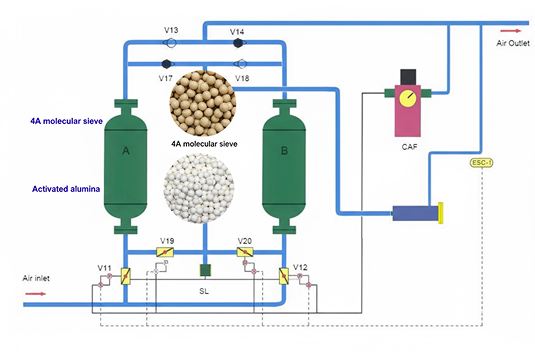

Application of Activated Alumina and Molecular Sieves in Cryogenic Air Separation

In cryogenic air separation, both molecular sieves and activated alumina play crucial roles in purifying the incoming air before it enters the low-temperature distillation process:

Activate Alumina Desiccant for Moisture Removal

Both Activated Alumina & Molecular Sieves are highly effective as a desiccant for removing water vapor from the compressed air. This is critical because moisture would freeze at cryogenic temperatures, leading to ice formation that can plug heat exchangers and other vital equipment in the air separation unit (ASU). Activated alumina often acts as a primary desiccant due to its high capacity for water.

Carbon Dioxide (CO2) Removal

Molecular Sieves are specifically designed to adsorb carbon dioxide. Like water, CO2 will solidify at cryogenic temperatures, causing blockages and operational issues within the ASU.

Hydrocarbon Removal

Certain Molecular Sieves are also vital for removing trace hydrocarbons (like acetylene) from the air stream. These hydrocarbons can be hazardous, as they can concentrate and potentially lead to explosive mixtures in the liquid oxygen section of the cryogenic distillation column.

Global Reach, Local Support

Serving clients in over 40 countries with reliable logistics and responsive service.

5 Ways to Prevent Activated Alumina Failure

Do not expose it to liquid water or saturated streams. Direct contact with liquid water or fully saturated vapor causes an extremely rapid adsorption process. This releases a large amount of heat, which can create steam, cause pressure spikes, and physically crack the alumina beads, a phenomenon known as “rehydration damage.”

Do not use it in systems with heavy oils, tars, or polymerizable compounds. These contaminants will coat the alumina’s surface and block its pores, a process called “fouling”. This fouling is often irreversible and prevents the alumina from adsorbing anything further or from being regenerated.

Do not use it in highly acidic or highly alkaline environments. Activated alumina is amphoteric, meaning it will dissolve in strong acids (pH < 5) and strong bases (pH > 12). This not only destroys the media but also contaminates your process stream with dissolved aluminum. It will be more stable in a near-neutral pH range.

Do not regenerate it at excessively high temperatures. While regeneration requires heat (typically 180-220°C) to drive off adsorbed moisture, using temperatures that are too high (e.g., above 250°C) for prolonged periods will cause “sintering.” This permanently collapses the porous structure, reduces the surface area, and destroys its capacity.

Do not neglect upstream filtration. Passing a gas or liquid stream containing particulate matter (dust, rust) or oil aerosols directly through an alumina bed will quickly plug it. This increases the pressure drop across the bed and coats the beads, preventing them from working efficiently. Always install appropriate filters beforehand.

Maximizing Performance: 5 Best Practices for Activated Alumina Applications

Deep drying of compressed air and gases

Activated alumina is a premier desiccant for achieving very low dew points, often down to -40°C and even -70°C in properly designed Temperature Swing Adsorption (TSA) or Pressure Swing Adsorption (PSA) systems. This is critical for instrument air and sensitive industrial processes.

Use it to remove fluorides, arsenic, and selenium from drinking water

It is a highly effective and cost-efficient adsorbent for these specific contaminants. For best results, the water’s pH should be adjusted to the optimal range for the target contaminant (e.g., pH 5.5 – 6.5 for fluoride removal).

Implement a counter-current regeneration process

The most effective way to regenerate a saturated alumina bed is to pass a heated, dry gas in the opposite direction of the normal service flow. This strips the moisture from the outlet, efficiently to the inlet. A subsequent cooling phase with the same dry gas is essential before putting the bed back in service.

Use it as a catalyst in the Claus process

In oil and gas refining, activated alumina is a crucial catalyst for converting hydrogen sulfide (H2S) and sulfur dioxide (SO2) into elemental sulfur. Its high surface area and thermal stability are ideal for promoting this reaction at high temperatures.

Ensure proper vessel design and loading

To maximize efficiency, the tower containing the alumina should be designed for even flow distribution to prevent “channeling,” where the gas bypasses the bulk of the media. Ensure the alumina is loaded carefully over support layers of inert ceramic balls to prevent crushing and guarantee smooth flow dynamics.

Activated Alumina Chemical formula is Al2 O3

Activated Alumina CAS number is (1344-28-1)

Activated Alumina FAQs & Concerns

What is activated alumina ?

Activated alumina (Al₂O₃) is a porous, high-surface‐area form of aluminium oxide. It is produced by de-hydroxylating aluminium hydroxide or any suitable precursor by calcination.

What is the CAS number of Activated Alumina?

The CAS number of Activated Alumina is 1344-28-1.

How is the correct grade or type chosen for an application?

Selection depends on factors such as:

- The contaminant or moisture load to be removed

- The operating conditions (temperature, pressure, flow rate, gas or liquid media)

- Desired service life / regeneration cycles

- Physical constraints (bed design, vessel size, pressure drop)

Our technical support engineers can advise on system design, proper media loading, bed configuration, regeneration strategy (if applicable) and choose the optimum grade for your process.

Can activated alumina be regenerated and reused?

Yes — many activated alumina beads can be thermally regenerated (for desiccant use) and reused for multiple cycles, subject to the contaminant load and chemical fouling conditions. Only in cases where irreversible fouling or chemical breakdown occurs, example strong acids/bases, oil/tar contamination, it can’t be regenerated or reused.

What are common causes of failure or reduced performance of activated alumina?

Common issues include:

- Exposure to liquid water (rather than vapour) or saturated streams — causes rapid adsorption, heat release and cracking (“rehydration damage”)

- Heavy oils, tars or polymerizable compounds fouling the pore surfaces

- Use in highly acidic (pH < 5) or highly alkaline (pH > 12) environments causing alumina dissolution

- Lack of proper particulate/oil filtration upstream, causing bed plugging or high pressure drop

These reduce performance, shorten service life, and may lead to breakdown.

What storage and handling practices should be followed for activated alumina?

Follow the practices to:

- Store in a dry, sealed condition; avoid exposure to moisture or ambient humidity before use

- Protect from impact/dust generation — high attrition beads lose efficiency

- Ensure vessels are designed for good flow distribution (to avoid channelling) and loaded over inert support layers (e.g., ceramic balls)

- Prior to use, check that upstream filtration and system design supports the media life.